Z Arm Mixer Manufacturer

-

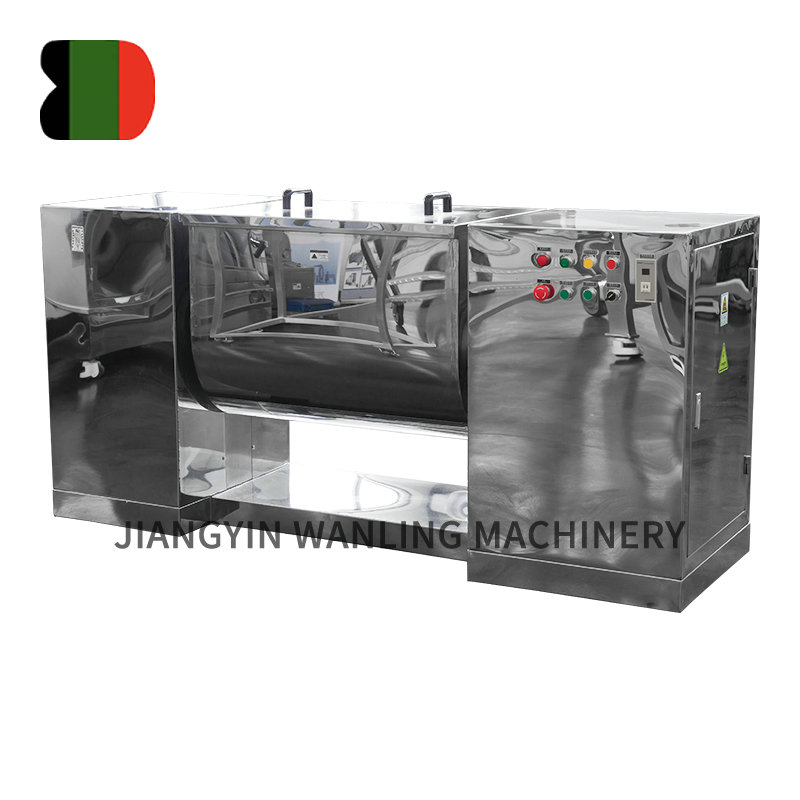

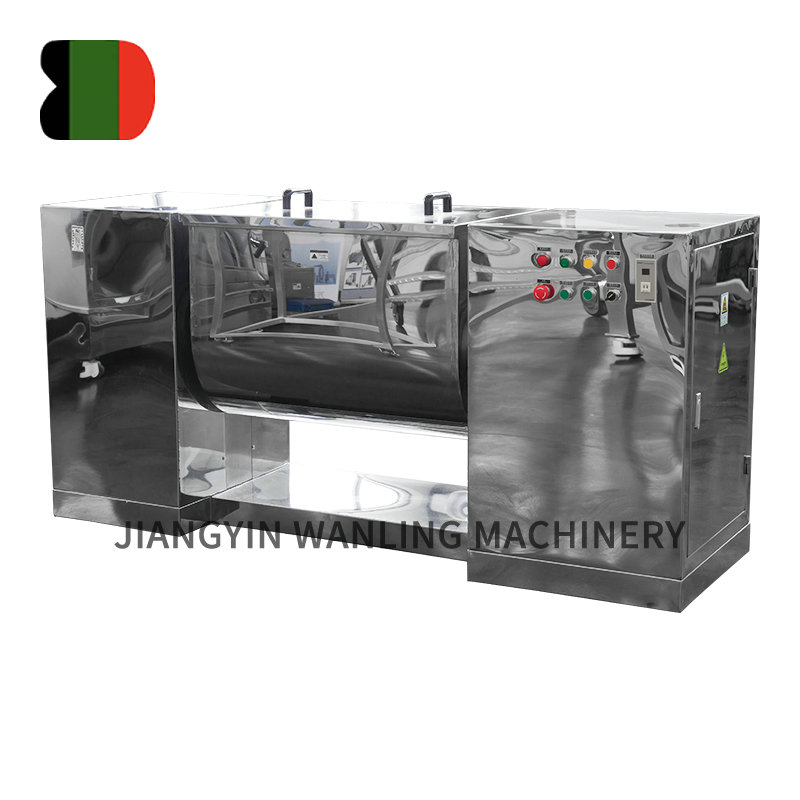

CH Single Paddle Flour Tank Mixer Machine

CH series groove mixer, mainly composed by the cell body and agitator, bracket, flip part, transmission part and electrical components. -

SCH Double Paddle Food Powder Mixer

SCH series groove mixer, mainly composed by the cell body and agitator, bracket, flip part, transmission part and electrical components. -

CH single screw powder tank mixer blender

The powder tank mixer is a horizontal type mixing machine, it can mix dry powder,granule and liquid. It have mixing blade, its z arm shape. ...

Z arm mixer is a horizontal mixer with Z-shaped blades. Widely used for mixing low viscosity and medium viscosity wet powders, pastes, and slurries in small and medium-sized production in the food and chemical industries. It consists of a slotted hybrid cylinder, single or double blades, an electric motor, and a support frame.

About Us

Honor

-

Honor

Honor -

CE

CE

News

-

Industry News 2026-01-20

Introduction to Fluid Bed Granulators in Powder Processing Fluid bed granulators have become a cruci...

View More -

Industry News 2026-01-12

Introduction to Tray Dryers Tray dryers are widely used industrial drying machines designed for dryi...

View More -

Industry News 2026-01-06

Introduction to Spice Grinding Machines Grinding machines for spices are essential equipment for bot...

View More -

Industry News 2026-01-04

Introduction to Industrial Drying Methods Drying is a critical process in pharmaceutical, chemical, ...

View More

Industry Knowledge Expansion

What is the design philosophy behind the Z-arm mixer?

The design philosophy behind a Z-arm mixer typically revolves around several key principles that aim to enhance the mixing process, improve efficiency, and ensure the machine is suitable for a wide range of applications. Here are some common philosophies that might guide the design of a Z-arm mixer:

Efficient Mixing: The Z-arm design is often intended to provide a thorough and efficient mix. The Z-shaped arms can move in a way that creates a folding or kneading motion, which is effective for blending various materials.

Versatility: The mixer is designed to accommodate different types of materials, from powders to liquids, and from light to heavy viscosities. This requires a design that is adaptable and can be adjusted or calibrated for specific mixing tasks.

Uniformity: The goal is to achieve a uniform mix every time. The Z-arm's motion can help ensure that all components are well distributed throughout the mixture.

Ease of Operation: The mixer should be user-friendly, with controls that are intuitive and easy to understand. This can include automated settings that simplify the mixing process.

Safety: Safety is a paramount concern in industrial design. The Z-arm mixer would incorporate features that minimize the risk of injury to operators and ensure compliance with safety standards.

Maintenance: The design should facilitate easy maintenance and cleaning, with components that are accessible and replaceable.

Energy Efficiency: Modern mixers are designed with energy efficiency in mind, using the least amount of power to achieve the desired results.

Scalability: The mixer may be designed to handle a range of batch sizes, allowing it to be used in both small-scale and large-scale operations.

Environmental Considerations: The design might also take into account environmental impact, such as noise reduction and the use of sustainable materials.

The exact design philosophy can vary depending on the manufacturer and the specific application for which the Z-arm mixer is intended. If you have a particular Z-arm mixer in mind, more detailed information can be provided based on the manufacturer's specifications and design goals.

Español

Español