Superfine Grinder Manufacturer

-

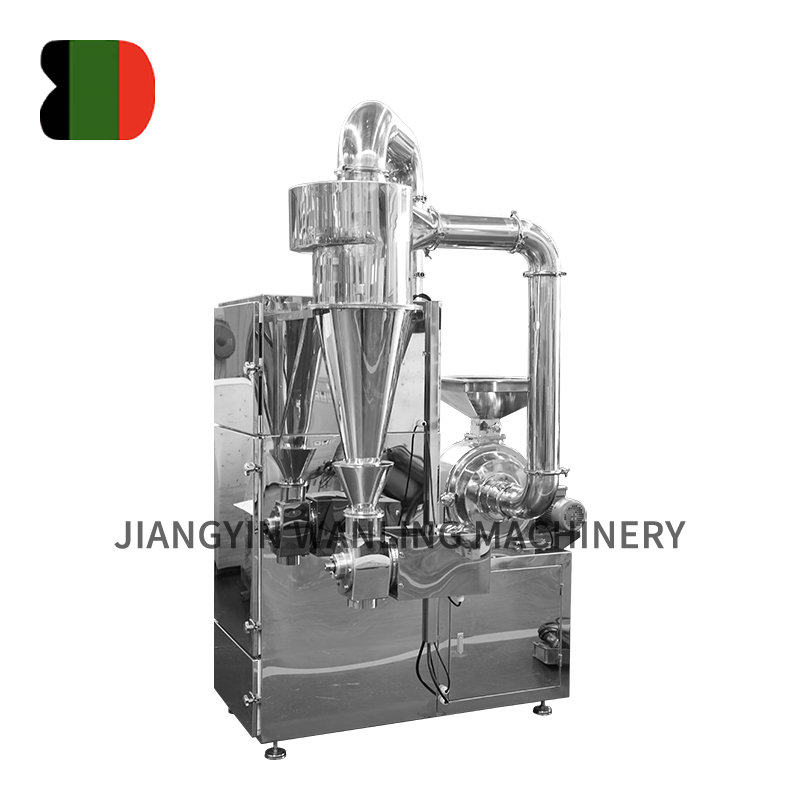

WLM Sugar Ultra Fine Powder Making Machine

The super fine grinder machine is made up of three parts: main machine, auxiliary machine and electric control box. It has the properties of... -

WLM Automatic Sugar Grinding Crusher Machine

The WLM automatic sugar grinding crusher machine is compatible with various types of sugar, but its relation to the sugar type goes beyond s... -

WLM sweet chilli powder making machine

The sweet chilli powder making machine is WLM superfine grinder,it can grind sweet chilli to fine powder.more than 100mesh. Though sweet chi... -

WLM flower fine powder making machine

The flower fine powder making machine is WLM-10 superfine grinder,it can grind flower to fine powder 80-600mesh, this grinder machine is dif... -

rice grinding machine

The rice grinding machine can grind rice to fine powder, more than 100mesh. It can work continuously, so its capacity is very big, its bigge... -

turmeric powder grinding machine

The turmeric grinding machine is WLM superfine grinder machine,it can grind material with fiber to fine powder , like roots,turmeric and etc... -

herb crusher

The herb crusher is ACM grinder machine, it is composed of feed hopper, grinding chamber, cyclone discharge part, dust collector, fan motor ... -

mushroom grinder

The mushroom grinder is ACM grinder machine, mushroom will be ground by grinding blade and air classifier wheel, fine powder will be pulled ... -

leaf grinder machine

The leaf grinder machine is WLM superfine grinder machine, this machine is good at grinding material with fiber, like leaf, tea, roots, herb... -

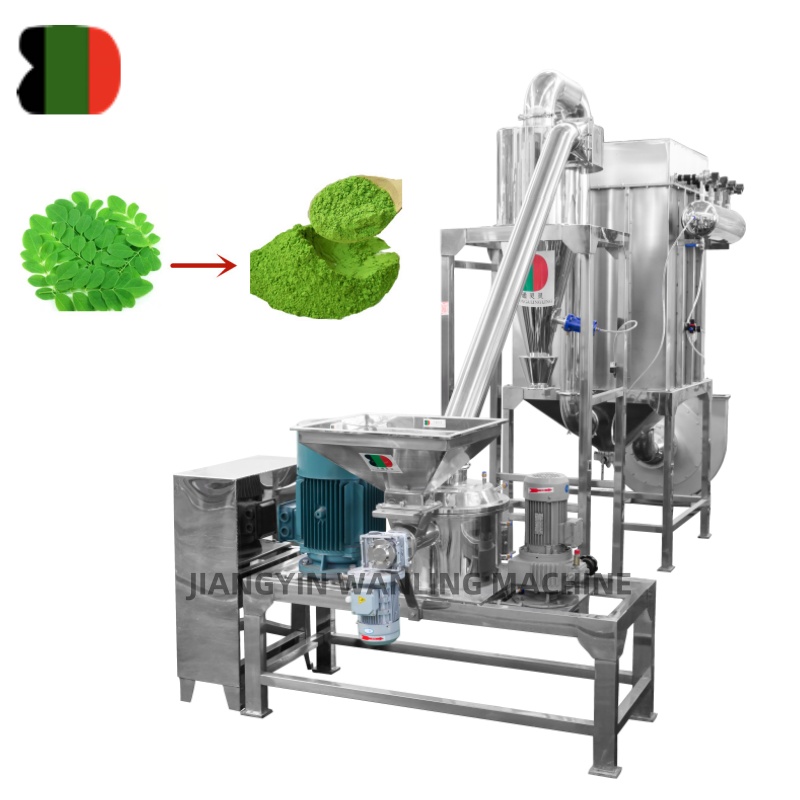

leaf grinding machine

The leaf grinding machine can grind many kinds of leaves, like morninga leaf, green leaf, tree leaf, henna and etc. It can grind leaf to ve... -

leaves grinder

The leaves grinder is hot sale in WANLING company, because it have good grinding effect on many hard material like leaves, roots, herb, dyes... -

WLM automatic sugar powder making grinder machine

Elevate your food processing capabilities with the WLM automatic sugar powder making grinder machine. Engineered for precision and efficienc... -

WLM automatic arabic gum grinding machine

Enhance your food processing operations with the WLM Automatic Arabic Gum Grinding Machine. Designed for superior efficiency and precision, ... -

WLM leaves powder making grinder machine

Process a variety of leaves with the WLM leaves powder making grinder machine, which is able to convert a variety of leaves into fine powder...

The Superfine grinder is a vertical reflection micro-grinder. It has many performance characteristics such as no screen, uniform particle size, etc. It is widely used in food, chemical, spice, pharmaceutical and other industries. It can freely adjust the size of the output particles. It can be used in conjunction with coarse crushers and screening machines to form a small, simple basic powder production line.

About Us

Honor

-

Honor

Honor -

CE

CE

News

-

Industry News 2026-01-20

Introduction to Fluid Bed Granulators in Powder Processing Fluid bed granulators have become a cruci...

View More -

Industry News 2026-01-12

Introduction to Tray Dryers Tray dryers are widely used industrial drying machines designed for dryi...

View More -

Industry News 2026-01-06

Introduction to Spice Grinding Machines Grinding machines for spices are essential equipment for bot...

View More -

Industry News 2026-01-04

Introduction to Industrial Drying Methods Drying is a critical process in pharmaceutical, chemical, ...

View More

Industry Knowledge Expansion

How does the Superfine grinder integrate with other equipment in a production line?

The integration of the Superfine grinder with other equipment in a production line depends on the specific needs and requirements of the processing operation. However, here are some general ways in which the Superfine grinder can be integrated with other equipment:

Feeding System Integration:

The Superfine grinder can be integrated with a feeding system that delivers materials into the grinder consistently and efficiently. This may involve using conveyors, screw feeders, or other feeding mechanisms to ensure a steady flow of material into the grinder.

Pre-processing Equipment:

Coarse crushers or shredders can be used upstream of the Superfine grinder to reduce the size of larger materials before they enter the grinder. This can improve efficiency and reduce wear on the grinder by pre-breaking down larger chunks or particles.

Screening and Separation Equipment:

After the material is processed by the Superfine grinder, it may need to be screened or separated to remove any oversized particles or impurities. Integration with screening machines or separators allows for the separation of the desired product from unwanted material.

Packaging and Storage Equipment:

Once the material has been processed to the desired particle size and quality, it can be integrated with packaging and storage equipment for final packaging and storage. This may involve conveyors, bagging machines, or other packaging equipment depending on the specific requirements of the end product.

Automation and Control Systems:

Integration with automation and control systems allows for seamless operation and monitoring of the entire production line, including the Superfine grinder. This may involve PLCs (Programmable Logic Controllers), SCADA (Supervisory Control and Data Acquisition) systems, or other control systems to optimize production efficiency and ensure consistent quality.

Are there any specific applications where the Superfine grinder excels?

Food Processing:

The Superfine grinder is commonly used in the food industry for processing various ingredients such as spices, herbs, grains, and food additives. Its ability to produce uniform particle sizes without the need for screens ensures consistency in flavor, texture, and appearance of food products.

Pharmaceuticals:

In the pharmaceutical industry, precision is crucial, and the Superfine grinder's ability to finely grind active pharmaceutical ingredients (APIs) and excipients to a uniform particle size is highly valued. This ensures accurate dosing, improved drug dissolution, and enhanced bioavailability of medications.

Chemicals and Pigments:

The Superfine grinder is utilized in the chemical industry for grinding and refining various chemical compounds, pigments, and dyes. Its ability to produce fine and uniform particle sizes enhances the quality and performance of these materials in applications such as coatings, paints, and specialty chemicals.

Cosmetics and Personal Care Products:

In the cosmetics and personal care industry, the Superfine grinder is used to micronize ingredients such as minerals, pigments, and powders for the formulation of skincare products, makeup, and toiletries. Its precise grinding capabilities result in smoother textures and better dispersion of ingredients in formulations.

Herbal Medicine and Nutraceuticals:

Herbal medicine and nutraceutical manufacturers benefit from the Superfine grinder's ability to finely grind botanicals and plant extracts to enhance their bioavailability and efficacy. By achieving a uniform particle size, the grinder ensures consistent potency and quality in herbal supplements and nutraceutical products.

Specialty Chemicals and High-Value Materials:

Industries dealing with specialty chemicals, high-value materials, and advanced materials often rely on the Superfine grinder to achieve precise particle size reduction without compromising material integrity. This is crucial for applications where material properties such as conductivity, solubility, or reactivity are critical.

Español

Español