Pin Blade Grinder Manufacturer

-

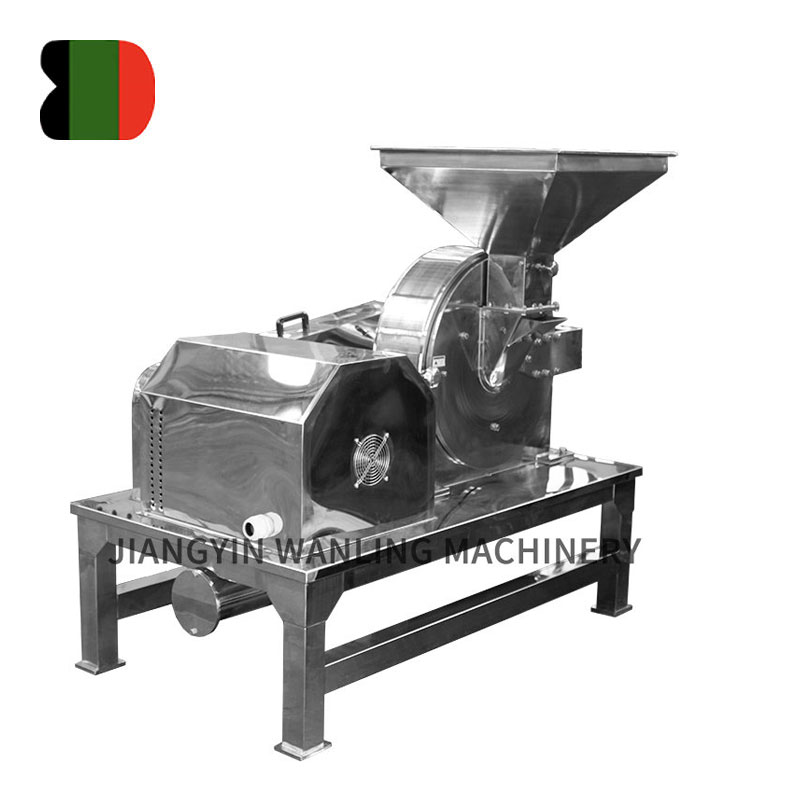

WLF stainless steel corn grinder machine

This corn grinder machine is WLF simple type pin mill,its structure is very simple,it can grind corn to powder 12-120mesh. The final corn po... -

WLF Sugar Mill With Dust Collector

This WLF Dust Collector Grinder machine is mainly used in chemical industry, medicine (TCM), food, spices, resin powder, besmear powder elv ... -

WLF Cyclone Type Chilli Grinding Machine

WLF pin cyclone deusting & grinding machine is a new generation of grinding machine, which is carefully designed and developed by our co... -

WLC Automatic Sugar Grinding Mill Machine

This WLC Complete Impact Pulverizer machine is mainly used in chemical industry, medicine (TCM), food, spices, resin powder, besmear powder ... -

WLF horizontal type pills grinder machine

This pills grinder machine is horizontal type pin mill machine, it can grind pills to powder 12-120mesh. This grinder machine have small mod... -

WLF automatic chilli grinding mill machine

WLF chilli mill machine can grind chilli to powder, it can work continuously for its cyclone discharge system. The mill machine is made of s... -

WLC high capacity sugar pin mill machine

This sugar mill machine use pin blade, it can grind sugar to fine powder 12-120mesh. The sugar mill machine can work continuously and it hav... -

black pepper grinder

The black pepper grinder is WLF pulse cyclone grinder, it can grind pepper to powder, the pepper powder size can be controlled by changing s... -

chilli powder making machine

The chilli powder making machine can crush dry chilli to powder 12-120mesh. The chilli powder size is controlled by screen mesh, clients can... -

sea salt grinder

This sea salt grinder is WLC complete grinder machine, the grinder machine can make stainless steel 316, because the salt have high corrosiv... -

sugar grinder

The sugar grinder is stainless steel machine, it can grind sugar to powder 12-120mesh, sugar is very easy to be ground, so grind sugar capac... -

sugar grinding machine

This sugar grinding machine is an industrial grinder machine, this machine can work continuously 24hours, the capacity also very big, the bi... -

sugar grinder machine

The sugar grinder machine is a very simple grinder, it is composed of feed hoppper, grinding chamber and discharge part. The grinder machine... -

turmeric powder making machine

The turmeric powder making machine can grind material into small size or powder, it can grind turmeric into powder around 60mesh. The grinde... -

salt grinding machine

The salt grinding machine is an automatic type grinder, with the cyclone discharge system, salt grinding machine can work continuously. The ...

Pin mill is a versatile crusher. It is suitable for food, chemical, pharmaceutical and other industries. This crusher has a small feed size and requires a coarse crusher to coarsely crush the material into smaller particles before entering the pin mill chamber. It comes with different size screens, with the smallest mesh being 120mesh.

About Us

Honor

-

Honor

Honor -

CE

CE

News

-

Industry News 2026-01-20

Introduction to Fluid Bed Granulators in Powder Processing Fluid bed granulators have become a cruci...

View More -

Industry News 2026-01-12

Introduction to Tray Dryers Tray dryers are widely used industrial drying machines designed for dryi...

View More -

Industry News 2026-01-06

Introduction to Spice Grinding Machines Grinding machines for spices are essential equipment for bot...

View More -

Industry News 2026-01-04

Introduction to Industrial Drying Methods Drying is a critical process in pharmaceutical, chemical, ...

View More

Industry Knowledge Expansion

What types of materials can be processed using a Pin Blade Grinder?

The Culinary Connoisseur: Food Products

In the culinary realm, precision is paramount. Pin Blade Grinders delicately handle an array of food products, from the robust flavors of spices and herbs to the subtleties of cocoa beans and coffee. Whether it's achieving the perfect consistency for seasoning blends or finely grinding grains for baking, these grinders offer unmatched performance.

Chemical Wizardry: Handling Complex Compounds

Chemical processes demand finesse, and Pin Blade Grinders rise to the occasion. From pigments and dyes to resins and adhesives, these machines navigate the intricacies of chemical compounds with ease. Whether it's refining catalysts or pulverizing fertilizers, Pin Blade Grinders ensure consistent results and optimal performance.

Pharmaceutical Precision: Crafting Medicinal Marvels

In the realm of pharmaceuticals, precision is not just a preference—it's a necessity. Pin Blade Grinders play a crucial role in pharmaceutical production, processing everything from active pharmaceutical ingredients (APIs) to herbal extracts and powdered medications. With the ability to achieve precise particle size distributions, these grinders ensure the efficacy and uniformity of pharmaceutical formulations.

Beauty in Balance: Cosmetics and Personal Care Products

Beauty is more than skin deep, and Pin Blade Grinders understand this implicitly. From powders for makeup formulations to skincare ingredients and beyond, these machines deliver the finely ground particles essential for creating luxurious cosmetics and personal care products. Whether it's achieving the perfect texture for a facial scrub or refining talcum powder to silky perfection, Pin Blade Grinders excel in the art of beauty.

Mineral Mastery: Harnessing Earth's Resources

From calcium carbonate to kaolin, Pin Blade Grinders tackle the complexities of minerals and ores with finesse. Whether it's refining industrial minerals for use in paints and coatings or processing minerals for the construction industry, these grinders ensure that every particle meets the stringent standards of quality and consistency.

How consistent is the particle size distribution produced by a Pin Blade Grinder?

The consistency of particle size distribution produced by a Pin Blade Grinder is a critical factor in various industries, determining the quality and performance of the end product. Pin Blade Grinders are renowned for their ability to achieve precise and consistent particle sizes, making them invaluable tools in numerous applications.

Precision Engineering: Ensuring Uniformity

Pin Blade Grinders operate on the principle of high-speed rotation combined with impact and shear forces, resulting in finely ground particles with remarkable consistency. The design of these grinders, featuring a series of interlocking pins or blades, ensures that materials undergo thorough and uniform grinding throughout the process.

Tight Control: Customizable Settings

One of the key features of Pin Blade Grinders is their ability to adjust parameters such as rotor speed, feed rate, and screen size, allowing operators to fine-tune the particle size distribution according to specific requirements. This level of control enables precise customization of the output, ensuring that every batch meets the desired specifications.

Reliable Results: Reproducibility and Accuracy

Consistency is not just about achieving uniform particle sizes—it's also about reproducibility and accuracy. Pin Blade Grinders excel in delivering reliable results batch after batch, thanks to their robust construction and advanced control systems. Whether processing food products, pharmaceuticals, or chemicals, operators can trust that the particle size distribution will remain consistent over time.

Español

Español