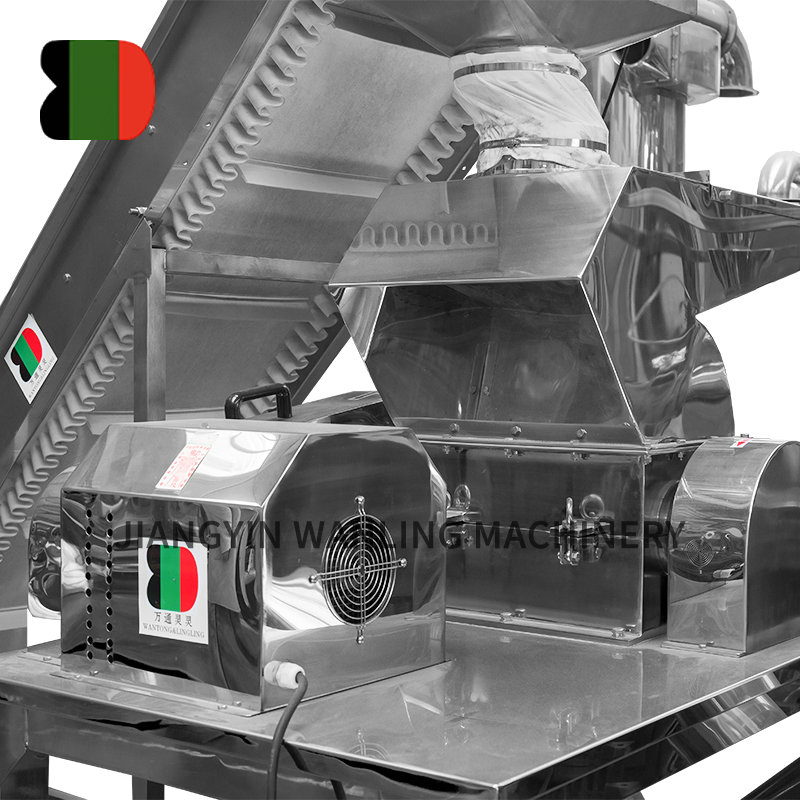

WFL type fluidized granulator is a new craft set combining the FLuidized bed technology and spraying technology to make granules in medical industry, foodstuff, chemical industry and so on.

WFL Cocoa Granule Making Fluid Bed Granulator

- Product Description

+86 13921209007

+86 13921209007

director@wtgrinderline.com

director@wtgrinderline.com

The powder grannle in the container(fluidization) appear in the state of fluidization.Fluid bed dryer granulator is preheated and mixed with clean and heated air.At the same makes the solution of adhesive solvent is fogged and sprayed into the contaier.It makes the some particles become granulating that contains adhesive.Being of unceasing dry through hot qir,the moisture in the granulation is evaporated and the adhesive is solidification.The process is carries out continuously.Finally it forms ideal,uniform and Porous granules.

|

Model |

3 |

5 |

15 |

30 |

45 |

60 |

90 |

120 |

200 |

300 |

500 |

|

|

Volume(L) |

12 |

22 |

45 |

100 |

155 |

220 |

300 |

420 |

660 |

1000 |

1500 |

|

|

Steam amount(KG/H) |

0.5-1 |

1-3 |

2-5 |

6-15 |

7-18 |

10-23 |

15-50 |

20-60 |

40-80 |

70-150 |

100-200 |

|

|

Processing amount(KG/batch) |

1.5-4.5 |

4-6 |

10-20 |

15-45 |

25-65 |

40-80 |

60-120 |

80-160 |

100-300 |

150-450 |

300-700 |

|

|

Steam |

Pressure(MPa) |

00.4-0.6 |

||||||||||

|

Consumption(kg/h) |

12 |

223 |

42 |

70 |

99 |

141 |

169 |

211 |

282 |

366 |

451 |

|

|

Compressed air |

Pressure(MPa) |

0.6 |

||||||||||

|

Consumption(m3/min) |

0.3 |

0.3 |

0.3 |

0.4 |

0.4 |

0.6 |

0.6 |

0.9 |

0.9 |

1.3 |

1.5 |

|

|

Temperature(℃) |

0-120 |

|||||||||||

|

Wind motor power(KW) |

2.2 |

3 |

4 |

5.5 |

7.5 |

11 |

15 |

18.5 |

22 |

30 |

45 |

|

|

Noise(Decibel) |

<75 (wind motor can separated) |

|||||||||||

|

|

|

About Us

Honor

-

Honor

Honor -

CE

CE

News

-

Industry News 2026-01-20

Introduction to Fluid Bed Granulators in Powder Processing Fluid bed granulators have become a crucial technology in the powder processing industry du...

View More -

Industry News 2026-01-12

Introduction to Tray Dryers Tray dryers are widely used industrial drying machines designed for drying powders, granules, liquids, and heat-sensitive ...

View More -

Industry News 2026-01-06

Introduction to Spice Grinding Machines Grinding machines for spices are essential equipment for both home kitchens and industrial food processing. Th...

View More

Español

Español